-

Staple Fiber Spunbond Nonwoven fabric Equipment

VIEW MOREThe equipment uses polypropylene (PP)、polyethylene terephthalate(PET )as raw material, using high speed hot air flow to stretch the polymer melt extruded by the nozzle hole, thus forming microfiber and collecting on the mesh curtain, and bonding itself to become a melt-blown nonwovens. Melt-blown cloth can be used in air, liquid filtration materials, isolation materials, absorbing materials, mask materials, thermal materials, oil absorption materials and wiping cloth and other fields.

-

PET Long Fiber Spunbond Equipment

VIEW MORECustomizable door width, for example; The annual production of 3.2 meter machinery can reach 5000 tons, with a weight of 10-260 grams

Technical Advantage

1. The whole line is well-structured and easy operating.

2. The whole line is highly automated.

3. Control elements are of well-known make high performance and reliable technologies .

4. The whole line are controlled by PLC and operated with touch-screen.

5. The allocation of the main frame auxiliary equipment can be specially designed and adjusted according to customers requirement.

-

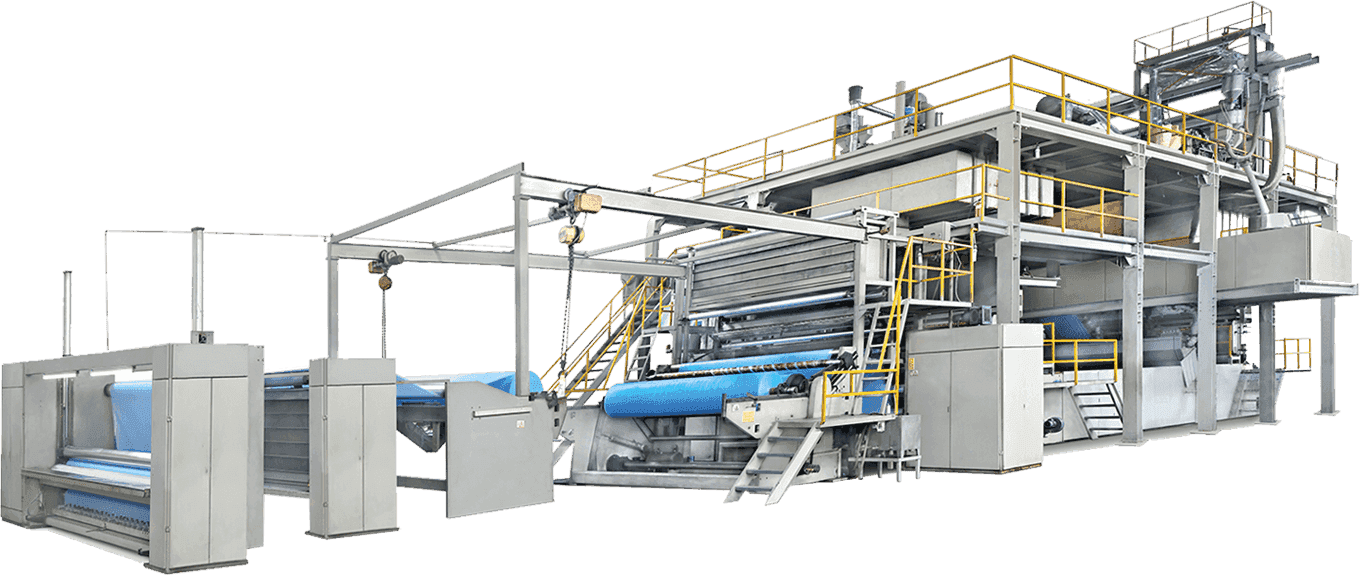

SMMSS Non-woven Production Line

VIEW MOREWeight range: 10-150g/㎡ Annual production range: 900-16000t/year

Main Feature

1. The whole line has a reasonable structure and is easy to operate.

2. The whole line is highly automated.

3. The control components are all brand-name products, with reliable performance and stable control.

4. The whole machine adopts PLC control and touch screen operation.

5. The layout of the host and auxiliary equipment can be specially designed and configured according to user conditions.

-

Spunlace Spunbond Nonwoven fabric Equipment

VIEW MORESpecifications: Customized Machine

Spunlaced nonwovens (spunlaced nonwovens) is a new kind of nonwovens processing technology. Spunlaced nonwovens (spunlaced nonwovens) are made by continuously spraying the web with high-pressure water, which makes the fibers move and displace in the web and rearrange and tangle with each other under the action of water, the fiber network can be reinforced to obtain certain physical and mechanical properties. SPUNLACED nonwovens are characterized by high strength, soft handle, good drape, no chemical adhesive and good air permeability.

-

Needle-punched Spunbond Nonwoven fabric Equipment

VIEW MORENeedle-punched spunbond non-woven fabric equipment is a popular technology used in the production of nonwoven fabrics. This equipment offers many advantages over other types of nonwoven production methods. One of the main advantages of needle-punched spunbond equipment is its ability to produce a wide range of nonwoven fabrics with varying degrees of thickness and strength.

Another advantage of needle-punched spunbond equipment is its ability to produce nonwovens with a high degree of uniformity and consistency. This is because the process involves using multiple needles to punch through a web of fibers, creating a dense and uniform product. This uniformity is essential for many applications, such as filtration, insulation, and geotextiles.

One of the most significant innovations in needle-punched spunbond equipment is the use of advanced control systems. These systems allow manufacturers to precisely control the speed, pressure, and temperature of the equipment, resulting in more consistent and uniform products. Additionally, these control systems can detect and correct any issues in real-time, reducing waste and increasing efficiency.

-

Heavy denier non-woven fabric

VIEW MORESpecification: Weight 30-80 grams

Product Introduction: Air Filter Composite

-

Polylactic acid non-woven fabric

VIEW MORESpecification: Gram weight 10-100

Product introduction: PLA non-woven fabric, also known as polylactic acid non-woven fabric, degradable non-woven fabric, and corn fiber non-woven fabric.

Usage: Tea bag, medicine bag.

-

PP Spunbonded Nonwoven Fabric

VIEW MORESpecification: Hot rolled: weight range 9-260, needle punched: weight 60-600, water spunlaced: weight 45-120

Product introduction: Non woven fabric PP is a type of fabric that does not require spinning and weaving. It simply orients or randomly arranges textile short fibers or filaments to form a fiber network structure, and then uses mechanical, thermal adhesive, or chemical methods to reinforce it. Non woven fabrics made of PP fibers are used for shopping bags, wrapping fabrics, geotextiles, and spunlaced fabrics.

-

PET Nonwoven Fabric

VIEW MORESpecification: Weight range 15-260, door width can be customized

Product introduction: Polyester (PET) spunbonded filament non-woven fabric is a type of non-woven fabric, which is made of 100% polyester chips. It is made of countless continuous polyester filaments through spunbond hot rolling. Also known as PET spunbonded filament non-woven fabric Features: Polyester (PET) spunbonded filament non-woven fabric is a water repellent non-woven fabric, and its water repellency varies depending on the weight of the fabric. The larger and thicker the weight, the better the water repellency. Polyester (PET) is resistant to high temperatures. Due to the melting point of polyester being around 260 ° C, it can maintain the stability of the overall dimensions of non-woven fabrics in environments that require temperature resistance. It has been widely used in heat transfer printing, filtration of transmission oil, and some composite materials that require high temperature resistance.

Polyester (PET) has been used in various fields due to its good air permeability, tensile strength, tear resistance and aging resistance.

Polyester (PET) spunbonded non-woven fabric also has a very special physical property: resistance to gamma rays.

-

R-PET Nonwoven Fabric

VIEW MORESpecification: Weight range 15-260, door width can be customized

Product introduction: RPET fabric (Recycled PET Fabric), also known as cola bottle eco-friendly fabric, is a new type of green and environmentally friendly fabric made from discarded mineral water bottles, cola bottles, and related non-woven waste. Its low-carbon source has created a new concept in the field of recycling. Usage: Luggage category: computer bags, ice bags, shoulder bags, backpacks, trolley cases, travel cases, makeup bags, pencil bags, camera backpacks, shopping bags, handbags, gift bags, tie pockets, baby strollers, storage boxes, storage boxes, medical bags, luggage materials, etc; Home textiles: bed four piece set, blanket, backrest, pillow, toy, decorative fabric, sofa cover, apron, umbrella, raincoat, sunshade umbrella, curtains, wiping cloth, etc; Clothing category: down jackets, windbreaker, jacket, waistcoat, sportswear, beach pants, baby sleeping bags, swimsuits, scarves, work clothes, conductive work clothes, fashion, costumes, pajamas, etc;

Other: tents, sleeping bags, hat materials, shoe materials, car interiors, etc.

-

Punching machine for nonwoven fabric( optional )

VIEW MOREProduct Description

The equipment is used for punching holes on the nonwoven fabric like SS, SSS and SMS and the fabrics will become fluffy and soft after the process of punching, and which can be applied to the hygiene materials, medical products such as lady napkins. adult diaper baby diaper, medical surgery pad and face mask materials.

-

Zlx-lm series lamination and laminating combination machines (optional)

VIEW MOREProduct Description

According to different orders and usage, ZLX-LM series lamination and laminating combination machines can finish the works of one-layer lamination, double layer lamination or laminating combination of two or more layers of base-materials. Machines of this series have been widely used in doing laminating or combination for Non-woven fabrics, paper, film, plastic sheet, textiles and a lot of composite materials. which modifies functions and adds value to products in industries such as food, packaging. advertising daily consumption, health care, medical industry and construction industry, etc.

A MATURE FACTORY YOU CAN COUNT ON

It is China professional PP PET Nonwovens Manufacturers, Nonwoven Machines Suppliers and Nonwoven Production Line Factory.

Jeremiah Machinery is located in Changzhou. Since its establishment, the company has always adhered to the management principle got talent-oriented and integrity, combined with foreign advanced information technology, management methods, and enterprise experience with the practice, so that the enterprise can always maintain its competitiveness in the fierce market competition and achieve rapid and stable development...-

HIGH TECHNOLOGY EQUIPMENT

Provide advanced high-quality after-sale service through our own hi-tech team and technological backup for our partners.

-

CUSTOMIZATION ABILITY

Make some modifications and upgrade models (such as auxiliary equipment, and weight counting function) according to customer's demand.

-

PROFESSIONAL TEAM

An excellent team composed of more than 100 experienced management personnel to escort the production of our customers.

HOT PRODUCTS

Jeremiah Machinery is one of the professional hi-tech manufacturer and supplier for long stick non-woven Fabric Poly ester solutions.

SALES NETWORK

We provide quality products and services to customers from all over the world.

-

150+ Partners

Jeremiah Machinery keeps investing on the research and development of new technology and long term partners witness together.

-

45+ Countries/Region

Creating value to and growing up with our partners is our mission.

SUSTAINABLE DEVELOPMENT

The creation of an efficient and sustainable transport system is critical.

-

Development--Green and Environmental Protection Priority

With the continuous development of science and technology, people's living standards are increasingly improving, and human demands on the Earth are also increasing. At the same time, the damage to the ecological environment on the Earth is also intensifying. Because nature is the basic condition for human survival and development, Jiangsu Jeremiah Machinery Co., Ltd. implements the concept of sustainable development in the development process, innovates environmental protection and green products to give back to the society, and contributes to environmental protection. -

Innovation--Implementation of Sustainable Concepts

Jiangsu Jeremiah Machinery Co., Ltd. is fully aware of the importance of green environmental protection, so in its own development process, it has always adhered to the concept of reducing production process, saving environmental protection and the impact of the whole life cycle of production and processing on the environment, and has never stopped innovating and developing sustainable green environmental protection products. We take the concept of green environmental protection as our first criterion for development, and only contribute to global ecological sustainability. -

Future---Environmental Protection Never Stop

With years of experience, Jiangsu Jeremiah Machinery Co., Ltd. has accumulated leading experience and technology in the industry, provided customers with the latest one-stop green environmental protection solutions, and contributed Jeremiah's strength in the update, growth and development of non-woven technology. At present, our company has obtained international environmental protection certifications such as GRS. In the future, we will continue to maintain the concept of green and sustainable development, linking economic benefits, environmental impact, and social reputation in the development process. The latest products will empower green environmental protection and assist the global sustainable development cause.

LATEST UPDATES

Provide you with the latest enterprise and industry news

-

Nonwoven Fabric Production Line: The core engine of efficient manufacturing

In the modern textile industry, Nonwoven Fabric Production Line has become a key technical system, which not only represents the innovation of materia...

READ MORE -

From the operating room to the fashion circle, the infinite possibilities of Nonwoven Fabric

In modern industry and daily life, there is a material that is quietly infiltrating into our food, clothing, housing and transportation. Nonwoven Fabr...

READ MORE -

PET Nonwoven Fabric: A new force in shaping the future textile industry

With the continuous progress of modern materials science, nonwoven fabrics have gradually leaped from marginal products in the traditional textile ind...

READ MORE -

Nonwoven Fabric machine: the forefront of technological innovation and market application

In recent years, nonwoven fabrics have been widely used in many fields such as medical, health, construction, automobile, and environmental protection...

READ MORE -

Long Spunbonded Nonwoven Fabric: A Revolutionary Material for Modern Applications

In the realm of materials science, the continuous evolution of textile technologies has led to the development of innovative fabrics that cater to div...

READ MORE -

Spunbonded Nonwoven Fabric: A Model of Innovative Technology and Diverse Applications

In the vast field of nonwoven fabrics, spunbonded nonwoven fabrics play an irreplaceable role in many industries with their unique process and excelle...

READ MORE

English

English русский

русский Français

Français Español

Español Türk

Türk Tiếng Việt

Tiếng Việt عربى

عربى

NEXT

NEXT